Cabbing Gear

If someone were to ask my opinion on the best cabbing machine in the world, I would undoubtedly say it's the one I own. Only problem is that there is only one like it, and it's mine, and I'm not selling it.

It seems like with most endeavors requiring machinery, over time certain companies bubble to the top of the industry because their products gain a reputation as being 'best in class.' People tend to like products that work well and are durable. When it comes to lapidary equipment, I'm not sure there's any clear winner. Or that's still in business.

If you forced my opinion, I would have to go with Highland Park (classic).

Highland Park is one of those extinct companies that is fondly recalled by some of the old timers who may still be using HP products. Note that there is a currently operating lapidary product called Highland Park doing business out of a small Texas town, but be aware that it only inherited the name from the original company. I'm intrigued by this new incarnation of HP because of new innovations they are exploring, but I haven't personally used the new HP equipment. They also seem to be focused on saws and haven't resurrected any of the original HP cabbing machines... yet.

About five years ago when I decided not to wait until retirement to get back into rock polishing (after a 40+ year haitus) I responded to an ad on Craigslist. A guy was selling a modified Highland Park cabbing combo. I remember the ad stating that this unit was no "break metal" machine like the competition was selling.

After the obligatory Craigslist haggle, we agreed on a price and I loaded it into the back of the Land Cruiser. The seller was a nice fellow who threw in a few slabs of interesting stone.

The model is an HP E-12, serial #40299. It has an 8" saw blade on the left and the right disk buffer had been modified for a 8x3 expando wheel, along with a custom splash guard. The arbor had 2 six inch SC wheels and one 6" chipped diamond wheel. The color was a bright blue, which I later figured must have been painted since I've never seen another blue HP machine.

Over the next year or so the machine evolved, customizing it to my druthers. It ended up with three 8" wheels. The manufacturor meant it for 2 wheels, but I put spacers in and drilled another hole for irrigation in the lid to accommodate 3 wheels. On the left is a 60 grit diamond wheel that could pulverize quartz in a few seconds. It took some dressing down with a huge piece of junk agate, but I eventually got it tamed.

Next was my middle wheel. I essentially traded a mini bike that had been sitting in my garage for a couple decades for a 60-90 (100 effective) grit sintered wheel.

The last of the 'shaper' wheels is a 360 grit diamond. And finally to the far right, I usually keep the expando belted with a worn 400 grit SC.

I've considered this machine at peak customization for the past couple years.

Another great feature of this machine is that it's completely servicable with generic parts. It's got a 1" main shaft supported by two standard pillow block bearings. The motor is a standard 1625 rpm, half-horse unit that drives the arbor by belt and pulley. The housing is really the only custom feature that would be hard to replace, but it's a very thick aluminum that seems to be able to endure several lifetimes of abuse.

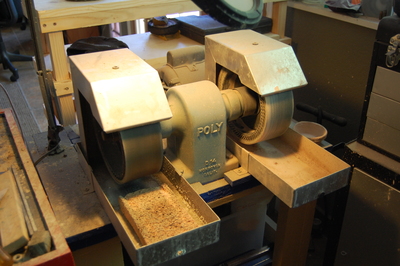

Another old standard in the lapidary world is the Poly arbor, also no longer in business. I picked one up on yet another Craigslist negotiation. He was an old timer who lived in Sun City and used it for polishing cut dinosaur turds. He also tried to sell me an HP 24" slab saw, enticing, but over my head at that time.

The Poly is a simple, two-wheel setup. Mine came with two 8x3 expandos that had been used for dry sanding. I customized it with a couple splash guards from Lortone and I was good for my 600 grit/pre-polish and polish phases of the cabbing process.

I've always been a scrounge with my lapidary obsession. Being of limited funds, it's difficult to justify dropping two large on a Genie or CabKing. Instead I have found pride and joy in cobbling together my own lapidary studio. I've met some kindred souls along my journey and have found that making cabs with my own custom equipment is very rewarding.

My next project? I've got a 14" drop saw in the shop that needs some serious de-rustification. It baked, uncovered, in the Arizona elements for over a decade. Should be fun!